ENMENUPUMPFINDCONTACT

ENMENUPUMPFINDCONTACT ENMENUPUMPFINDCONTACT

ENMENUPUMPFINDCONTACT

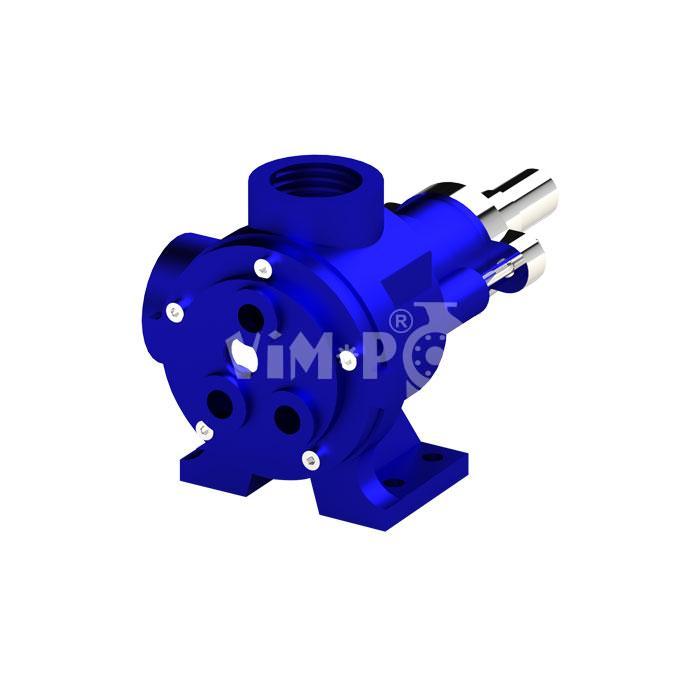

Internally eccentric pumps are a type of positive displacement pump that utilize a rotating internal rotor and a stationary external stator to create a pumping action. The rotor is shaped in such a way that it remains eccentrically positioned within the stator during rotation, causing the volume of fluid within the pump to change and resulting in the displacement and transfer of the fluid.

These pumps are highly efficient and versatile, making them suitable for a wide range of applications in various industries. In this article, we will provide an overview of internally eccentric pumps, their advantages, and their applications.

Internally eccentric gear pumps operate on the principle of positive displacement, which means that a fixed amount of fluid is displaced with each rotation of the rotor. The rotor has an eccentric shape, which causes the fluid within the pump to move from the inlet to the outlet as the rotor rotates.

As the rotor turns, the vanes of the rotor sweep along the inside surface of the stator. This creates a series of chambers between the rotor and stator that increase and decrease in volume as the rotor turns. This causes the fluid within the pump to be displaced and transferred to the outlet.

Internally eccentric pumps offer several advantages over other types of pumps, including;

Internally eccentric pumps are used in a wide range of industries and applications, including;

Internally excentrical pumps, also known as eccentric screw pumps, are widely used in a variety of industries due to their unique ability to handle viscous fluids, slurries, and even delicate materials. These pumps consist of a helical screw that moves within a stator, generating a progressive cavity. The eccentricity of the screw and stator ensures that the fluid is transported smoothly, without pulsation, making it ideal for applications requiring precision and gentle handling of the fluid.

In the chemical and pharmaceutical industries, these pumps are essential for transferring sensitive substances, including viscous chemicals, slurries, and even high-purity fluids. Their ability to provide a consistent flow rate without shear stress makes them valuable in situations where the integrity of the fluid must be maintained. Furthermore, in food processing, they are employed for the handling of thick liquids such as pastes, syrups, and doughs, where traditional pumps may struggle due to the high viscosity of the materials.

Additionally, in wastewater treatment, internally excentrical pumps play a crucial role in transporting thick sludge, ensuring that the material is moved without clogging the system. The pulp and paper industry also benefits from their use, where these pumps are employed to move slurries and pulps with varying consistencies. The ability of these pumps to handle solids and liquids in suspension makes them versatile and reliable in sectors that require the movement of challenging fluids.

Internally eccentric pumps offer numerous advantages over other types of pumps, making them a popular choice for a wide range of applications in various industries. Their high efficiency, high pressure, low shear, self-priming capabilities, and low maintenance requirements make them an ideal choice for pumping fluids with varying viscosities and densities. If you are in need of a reliable and efficient pump for your operations, consider Vimpo Pumps' range of internally eccentric pumps.

Vimpo Machine Pvt. Ltd. (Fabrika)

Plot No. PAP-160, Village - Shinde, TAL-Khed.Dist- Pune, Chakan phase-2 Maharashtra-410501

+91 6359-818748

Venta-Tech LLC

sale@venta-tech.com

+380671229797 Whatsapp/Telegram

АСТРА

Krasnoshkolnaya Embankment 2, Office 22, 61050 Kharkiv

+380577329505

TREMCO Transport Equipments Manufacturing Company

Sabhan, Block 11, Building 224 Sabhan, Block 9, Building 100

+965 9720 6090

EAST EG ENGINEERING AND SERVICES TECHNOLOGY SAE

30 ST 276 New Maadi, Cairo 11742, Egypt.

Tel: +20 2 2519 3383 |Ext 139 Fax: +20 2 2519 3381